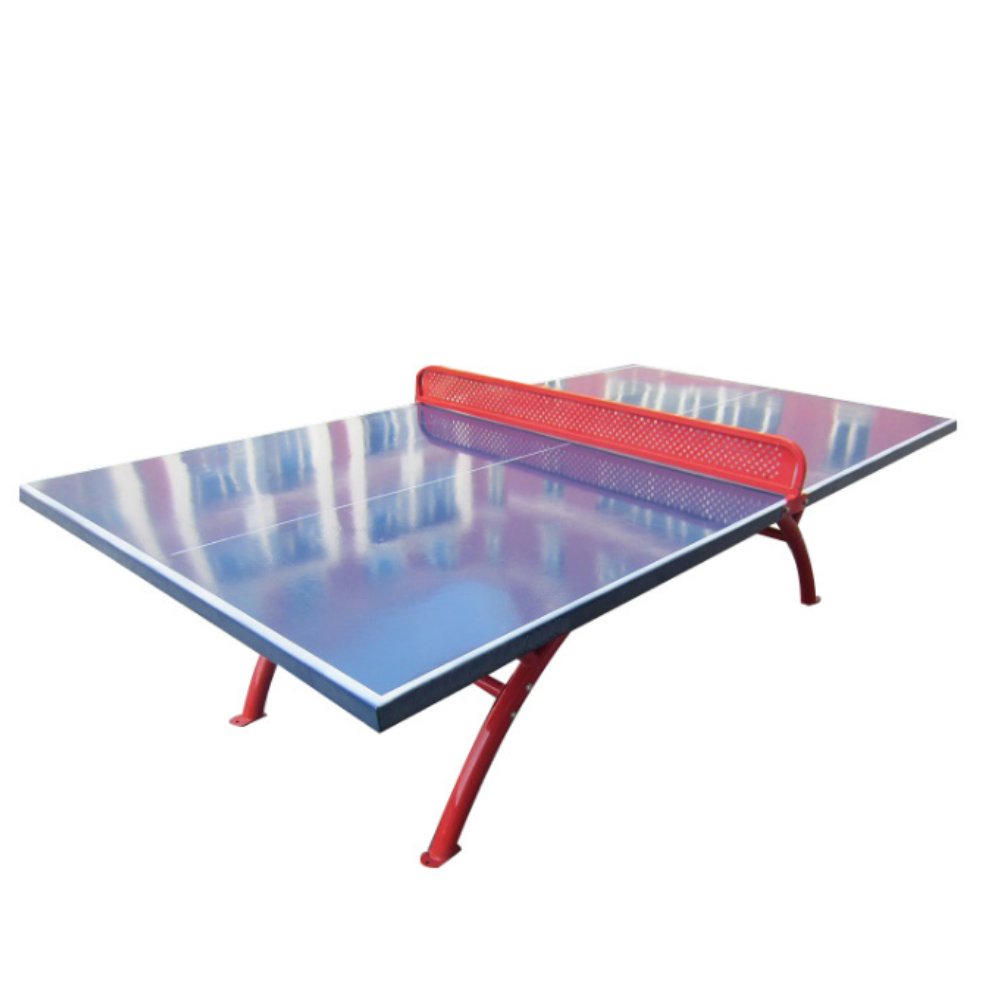

Folding Tennis Table Tennis Tables with Wheels Professional Table for School House Competitions Ping Pong Table/Tennis Table (Pink Pong Table)/Tennis table

1,980.00₾ Первоначальная цена составляла 1,980.00₾.1,386.00₾Текущая цена: 1,386.00₾.

1 in stock

Safe Payments

| Material: | SMC |

| Size: |

|

| Size in packed condition (length, width, height): | 162 x 150 x 12 cm |

| Color: | Blue; |

| Wheel diameter: | 75 mm; |

| Table thickness: | 14 mm; |

| Features: |

|

| Weight: | 83 kg; |

Material SMC is a mixture of polymer resin, fillers, fiber reinforcement, catalyst, pigments, stabilizers, release agents and thickeners. The production of SMC is a continuous in-house process. This process produces high-strength, complex parts of various sizes. The corresponding metal pedestals are installed in a hydraulic molding press; The heated mold halves are closed and pressure of up to 2000 psi is applied. Cycle times range from one to five minutes, depending on part size and thickness. Compression molded fiberglass parts are characterized by a mesh size and shape, two excellent finished surfaces, and outstanding part-to-part repeatability. Trimming and finishing costs are minimal. In-tool coatings and a vacuum system are available to enhance the paintability of the surface, eliminating the need for primer. Color compounds can be customized. Advantages of SMC molded parts include: 1. Good dimensional stability, including excellent heat resistance. 2. Pigmentable for molded color; 3. Excellent visual retention in cold and hot environments. 4. Suitable for outdoor applications that include UV exposure and water;

Delivery Time

Tbilisi

Standard

Until 17:00 of the current day

The ordered order will be delivered in two working days.

Regions

Delivery takes place according to a predetermined schedule

See the schedule as a link: Click

Courier service does not work on weekends.

Items ordered on Friday will be delivered to the address on Tuesday.

Delivery service is available from Monday to Friday

If you have any questions or would like to use the express delivery service, please contact us.

Installment Policy

We have 0-% TBC, Bank of Georgia , Credo Bank Installments

- Select the desired product for which the total amount is 100 or more GEL

- Click to pay in installments or choose on checkout page

- Fill out the application on the TBC Bank page and wait for confirmation

You May Also Like

Folding Tennis Table , Tennis Tables With Wheels – Professional Table School Home Competition Game Ping Pong Table/Tennis table

Tennis Table SMC Table Tennis Tables Small Tennis Table Ping Pong Outdoor Table Tennis School Community Spaces Toy/Tennis Table Outdoor Use (Pink Pong Table)

Tennis Table SMC Table Tennis Tables Small Tennis Table Ping Pong Outdoor Table Tennis School Community Spaces Toy/Outdoor Waterproof Tennis Table (Pink Pong Table)

tennis racket BUTTERFLY /table tennis racket (ping pong, tennis)

Professional tennis racket/table tennis racket (ping pong, tennis) avessa

Professional tennis racket/table tennis racket (ping pong, tennis) avessa

Related Products

purple

purple  green

green  Dark Blue

Dark Blue  red

red Badminton Set 2 Racquets in Case, Tennis Racquets/Sports BADMINTON RACKETS

26.00₾ green

green  Dark Blue

Dark Blue Badminton Set 2 Racquets in Case, Tennis Racquets/Sports

29.00₾Delivery throughout Georgia